Mobile Real-Time Target Machine

The Mobile real-time target machine is Speedgoat’s mainstay target computer for field and in-vehicle use, confined areas, or harsh environments.

It is used in a broad range of application areas and industry sectors, such as Rapid Controller Prototyping (RCP) for the automotive and energy sectors, and PLC plant simulation.

This high-performance target computer is Speedgoat’s answer to other small form factor designs based on PCI/104, COM Express, PCIe/104, etc.

MathWorks software products are optimized to guarantee the best real-time performance, workflow integration and usability with Simulink Real-Time™ and Speedgoat target machines.

Speedgoat builds and optimises its target machines for use with Simulink Real-Time, as well as guaranteeing that each target machine is configured to meet specific requirements, such as supporting model complexity, sample rate, data storage, I/O, and environmental.

Every target machine comes with the Speedgoat library, providing Simulink driver blocks to support all interfaces and simple Simulink models to get up and running quickly.

Each Mobile real-time target machine is configured to meet model complexity, interfacing and sampling rate requirements. By leveraging multiple CPU cores and FPGAs for algorithmic execution, and lowest latency analog and digital I/O connectivity, closed-loop sample rates of up to several MHz can be achieved.

For applications requiring closed-loop sample rates above 20 kHz, Speedgoat typically recommends partitioning algorithms between the Speedgoat CPU and installed Speedgoat FPGA-based I/O modules.

- Concurrent execution on multiple CPU cores and FPGAs

Simulink Real-Time provides powerful technology to automatically distribute models to multiple cores. Such technology is ideal for real-time applications that introduce a high algorithmic load, as is often the case with plant simulations. Execution and synchronization of applications running on multiple target machines is supported via dedicated shared memory I/O modules.

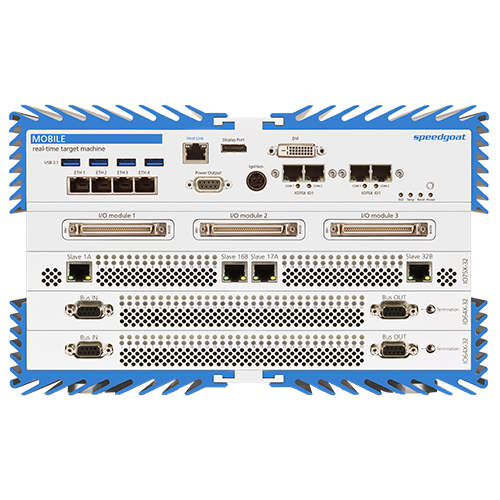

For closed-loop sample rates from 20 kHz up to several MHz, the advanced cooling concept of the Mobile real-time target machine allows the installation of multiple powerful Speedgoat FPGA-based I/O modules, supported by HDL Coder from MathWorks. This allows you to build, deploy and run integrated HDL real-time code created from Simulink Real-Time on the target machine.

- High speed serial links between FPGA modules

Simulink Programmable FPGA modules can be interconnected via on-board gigabit links, supporting the Xilinx Aurora protocol, allowing FPGA to FPGA communication in less than 10μs.

The Mobile real-time target machine supports a vast range of I/O to connect with your hardware.

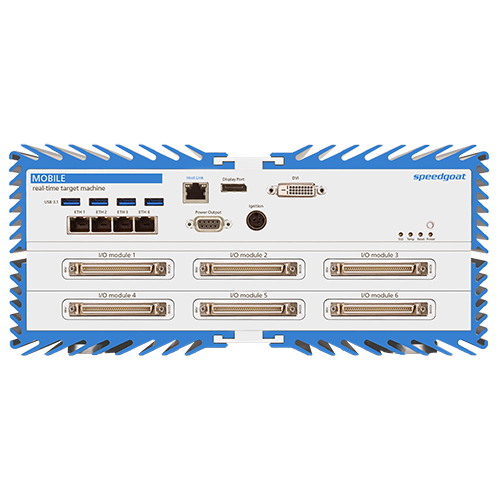

Every Mobile real-time target machine comes default with on-board I/O as well as five I/O slots supporting the installation of a large range of I/O modules. Additionally the Mobile target machine can be expanded to host up to fourteen I/O slots.

I/O Modules

Speedogat I/O modules offer an easy, flexible way of adding a large variety of I/O connectivity to your real-time target machine.

On-board I/O Connectivity

The following I/O connectivity is available as standard on the Mobile real-time target machine:

- 1 x Ethernet port for XCP Slave and TCP/IP link with Simulink development computer

- 3 x Ethernet port supporting by default:

- TCP/IP

- EtherCAT Master

- Real-time UDP

- PTP IEEE-1588

- Additionally supported with run-time license:

- Modbus TCP

- Modbus RTU

- IEC 61850

- DNP3

- OPC UA

- MQTT

- 2 x RS232 (2 x RS422/RS485 optional)

- 4 x USB 3.1

- 1 x DisplayPort 1.2, 1 x DVI-D

- 1 x Ignition switch for remote-control startup and shutdown

This target machine is designed to withstand high levels of shock and vibration – typical when used in off-highway vehicles, helicopters, or planes. The mainboard, internal power supply, and I/O module carriers form a single rigid unit, isolated from the case to prevent unwanted strains which could occur in environments with varying temperatures.

No mechanically moving parts are used (e.g. CPU fans, hard disk). The I/O connectors of the I/O modules are brought out directly, eliminating the need for internal cabling. The enclosure is EMI shielded and all connectors are ESD protected. IP67 is optionally available.

The advanced heat dissipation concept is based entirely on thermal conduction. By using solid aluminum heat sinks and optimized internal heat distribution, temperature ranges of -20°C to 60°C (optionally -45°C up to +75°C) can be supported.

The Mobile real-time target machine not only provides rich on-board I/O including EtherCAT Master, real-time UDP, PTP (1588), XPC over Ethernet, RS232, and USB WebCam support, but allows for flexible I/O expansion.

The standard configuration has a total of five slots for I/O modules, with the following form factors:

- 3 x PMC/XMC/CMC

- 2 x mPCIe

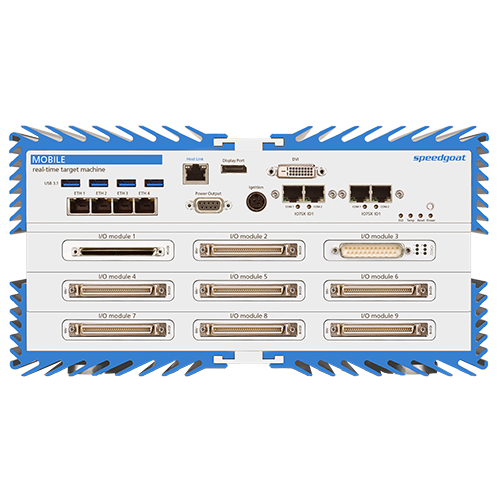

To install further I/O modules, up to three expansion layers can be added, each providing an additional three PMC/XMC/CMC slots.

Fully expanded, a total of fourteen I/O modules can be installed.